|

Zhoushan Lifeng Screws Machinery Co., Ltd

|

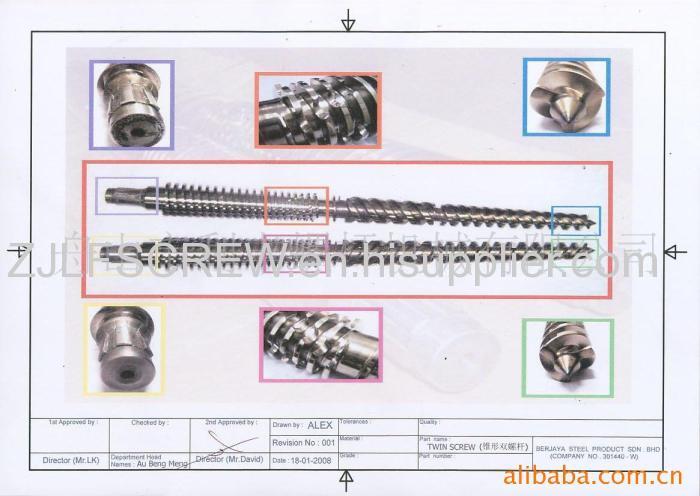

Spot High Quality Plastic Extusion Machine All Type Conical Twin Screw and Barrel

| Price: | 200.0~5000.0 USD |

| Payment Terms: | T/T,L/C,D/A,D/P,WU |

| Place of Origin: | Zhejiang, China (Mainland) |

|

|

|

| Add to My Favorites | |

| HiSupplier Escrow |

Product Detail

Specification:

1. Conical Bimetallic Twin Screw And Nitritding Cylinder barrel

2. The screw and barrel can be customized.

Spot High Quality Plastic Extusion Machine All Type Conical Twin Screw and Barrel

Product Description

Specialized equipment, precision work, all kinds of screw and barrel are made of 38CrMoAlA. The products are with excellent wearresistance and corrosion resistance after anion nitriding, which can improve the working life. Every technical index is strictly according to JB/T8538-1997 and ISO 9002.

Spec of conical twin screw and barrel

Conical twin screw | |

Specification | Φ32/Φ75~Φ92/Φ188 |

Technical Index | |

Nitriding Depth | 0.5~0.8mm |

Nitriding Hardness | HV950~1020° |

Nitriding Fragility | Less than grade 1 |

Surface Roughness | Ra0.4 |

Linearity | 0.015mm/m |

Double Alloy Hardness | HRC55~62℃ |

Double Alloy Depth | 2mm |

Production Introduction:

1.Material:38CrMoAlA, Ntriding Treatment,Surface Hardness:HRC55℃,58℃.

2.Material: Base Material, surface corner angle of screw adopt double alloy imported alloy steel, with special treatment which can improve the wear-resistance of barrel efficiently, as well as extend the working life.

Technical Index:

1. Produce application: For extrusion, Conical twin screw and barrel, Parallel twin screw and barrel.

2. Ntriding Depth: 0.4~0.7mm

3. Nitriding Hardness: Above HV960~1040°

4. Linearity:0.015~1000mm

5. Chroming: 0.02~0.20mm

6. Apply to: Normal plastic, PP, PE, ABS, PVC, Raw material, HDPE, Tubular product, PCPO, PET sheet.

We are specialized in producing conical twin screw and barrel or conical thermomental twin screw and barrel for conical extrusion, whcih apply to glass reinforced plastics, modified engineering plastics filled with calcium carbonate, U-PVC(Tubular, Sheet product), PVC rubber tube.

As per your requirements, the screw can be made with whole alloy or partial alloy, and the barrel can be made with inner bore whole alloy or partial alloy.

Nitriding steel material:38CrMoAlA, 31CrMoV9(Abroad)

Thermomental barrel material: Base mental 38CrMoAlA, 40Cr, 4CrMo

Thermomental screw material: Base mental 38CrMoAlA, 31CrMoV9(Abroad)

As per your requirements, the screw can be made with whole alloy or partial alloy, and the barrel can be made with inner bore whole alloy or partial alloy.

Powder of barrel (iron-based):

JH-A | Special use alloy |

JH-B | Excellent wear resistance, high corrosion resistance, shock resistance, crack resistance |

JH-C | Excellent wear resistance, high corrosion resistance |

JH-D | Excellent wear resistance |

Powder of barrel (nickle-based):

JH-A | Special use alloy |

JH-B | Excellent wear resistance, high corrosion resistance, shock resistance, crack resistance |

JH-C | Excellent wear resistance, high corrosion resistance |

JH-D | Excellent wear resistance |

Conical twin screw is different with conical single screw, the channel depth of conical single screw is constant in the whole length, however, the channel depth of conical twin screw is upward sooth from the screw head to feeding section. Hence, we nearly only use conical twin screw.

Due to the channel depth of metering section is much deeper, short screw pitch also can realize big channel volume, lead to material can stay much longer time, so that the material can be warmed up well. What is more, the screw is compressed continuously from feeding section to compression section, so the material is compressed in every section because of the conical construction.

Short diameter conical twin screw can realize the fusant more welldistributed by enlarging the middle section and the wind land gap of metering section edge.

We adopt advanced technology at home and abroad and keep improving. In the mean time, we also repair various used screw and barrel, maintain various used machines, to make the highest value at lowest cost.

With abovetenyearexperience, we have our own professional service department, to satisfy different customers. Your inquiry will be replied soonest as we can, and we can give you an advice on choosing the machine, please give us an opportunity to cooperate with you.

Company Introduction

With over 10 years of production, LIFENG Machine offers a full line of screw, barrel and assembly parts for injection/ extrusion molding machine.

Quality check is the last stage before deliver the goods to customer and the most important stage in our production process. Therefore, in order to carry out our target of achieving zero defects, strict quality check is conducted at every stage of the production. Start from the designing, manufacturing and up to final stage of packing, strict quality check is carried out. This is to ensure that only goods of high quality are delivered to our customers.We can offer you different standard of screws and barrels.In case any enquiry of our production or any question,design plan and quotation, don't hesitate to contact me or visit our website atwww.zjlf-China.com

Not only we are offering high quality products, we also provide depth information about how to use our products.

No minimum orders, 100% guarantee, full warranty. Quantity break pricing.

Packing and Shipping

Contact us